Our state-of-the-art in-house acoustics lab enables precise testing and development of superior soundproofing solutions. By simulating real-world conditions, we ensure that every Calma pod delivers exceptional acoustic performance and unparalleled voice clarity.

Innovation

The constant evolution of technology prompts us to reassess our product development approach each day. Calma is produced in the collaborative ecosystem of Nurus; integrating R&D activities into design and development processes, making sure that every product is engineered to perfection.

Automation and Efficiency

Our 45,000 sqm production facility features fully automated production lines, ensuring unmatched efficiency and precision. This automation enables us to maintain high standards of quality while optimizing production times, reflecting our commitment to delivering excellence swiftly and reliably.

Research to Trigger New Habits

Our expanding in-house R&D community is dedicated to innovation across a range of projects. By fostering a culture of research and development, we continuously explore new materials and technologies to shape future habits and drive industry advancements.

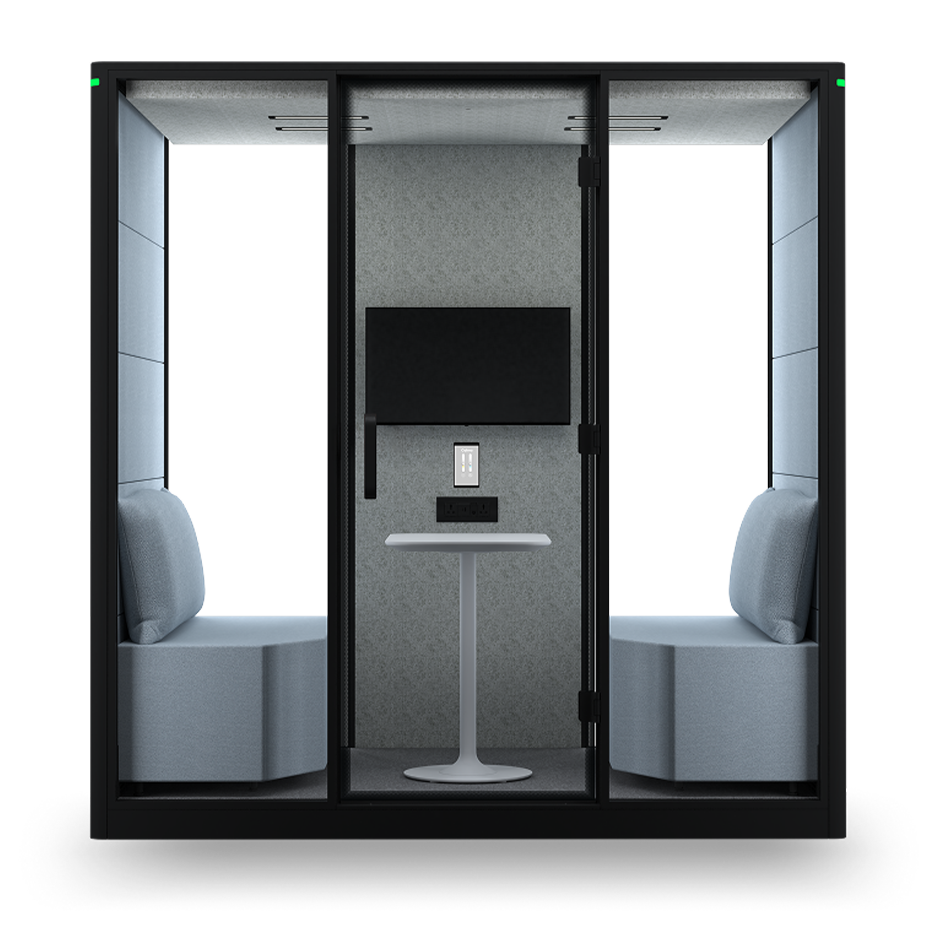

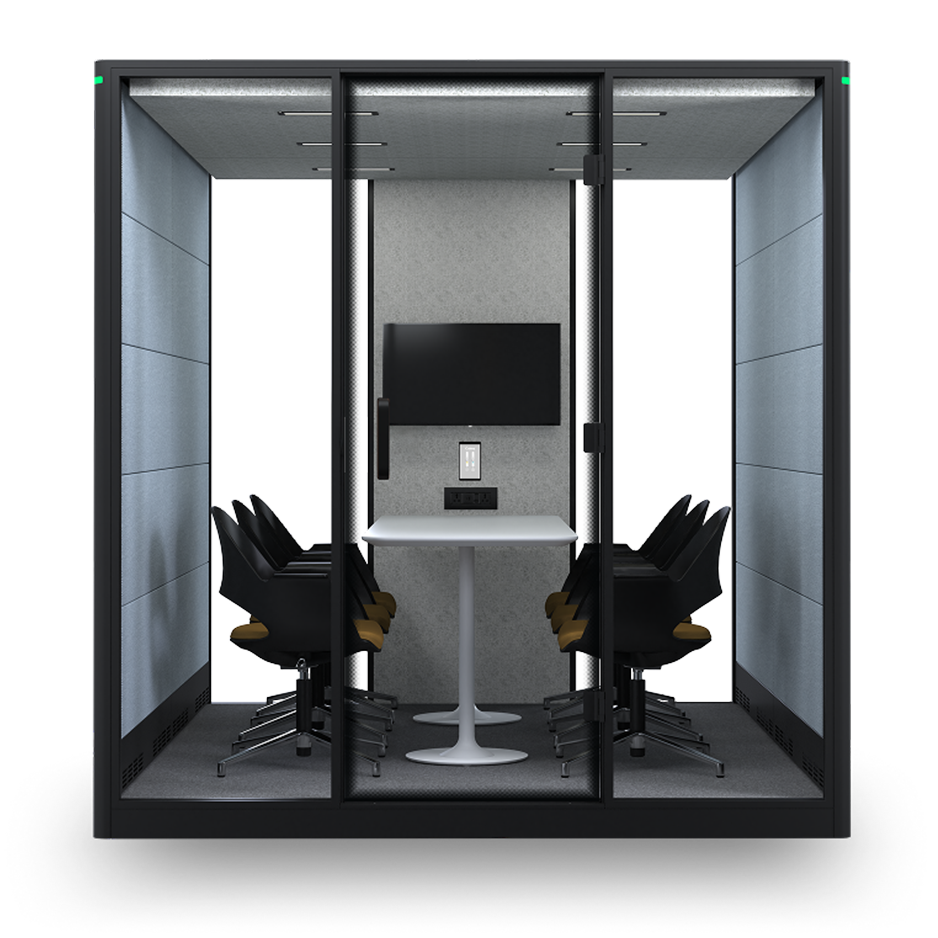

Design For Re-Configuration

At Nurus, our design team, Nurus D Lab, collaborates closely with the R&D team to create precise designs optimized for efficient production. By focusing on human-centered principles and technological advancements, we ensure that each design meets user needs while maximizing functionality. This synergy minimizes waste, including time, and promotes sustainability. Our commitment to efficient production extends to the ease of assembly and disassembly of our products. Optimized production processes result in designs that are not only innovative but also practical, ensuring quick and straightforward assembly. This approach enhances user experience and reinforces our dedication to quality and efficiency.